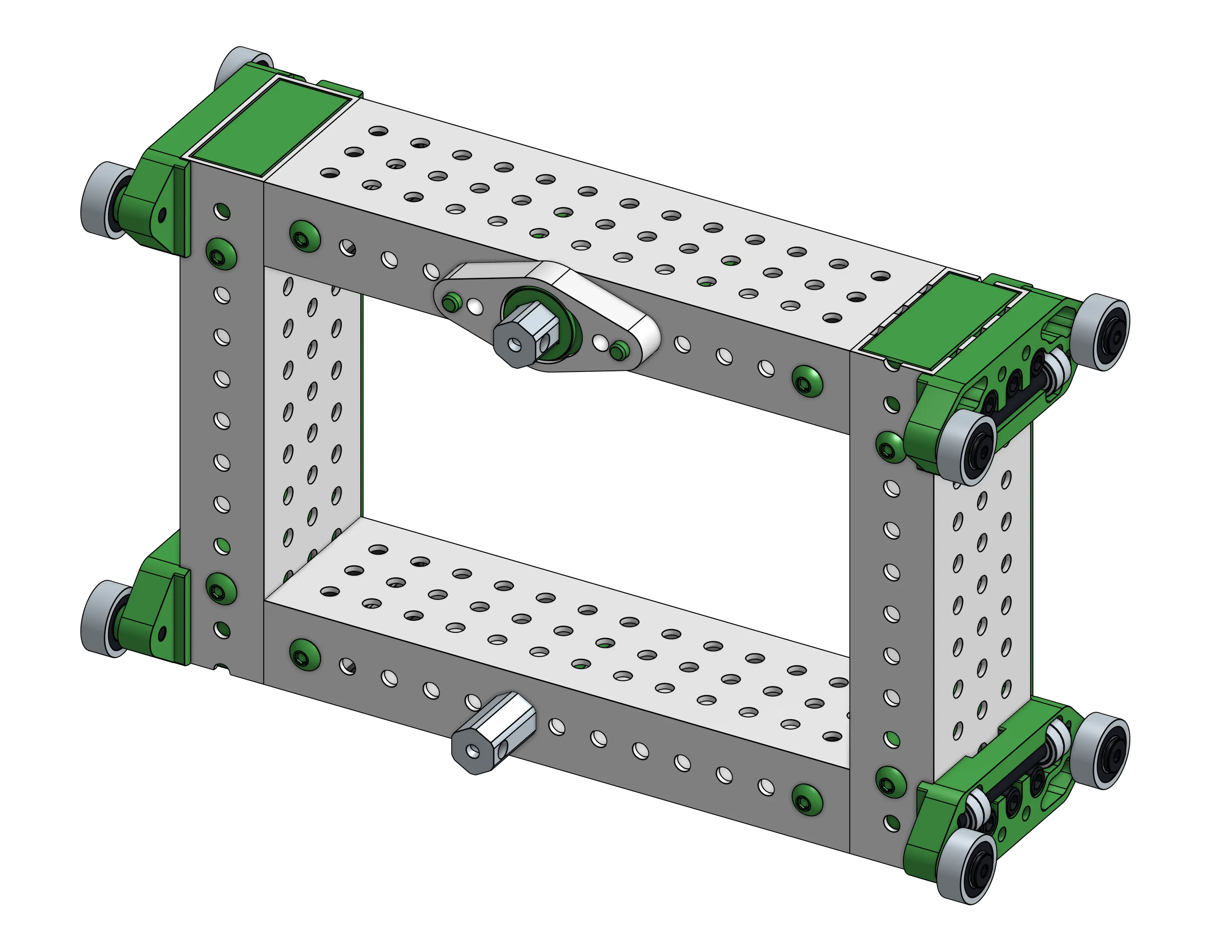

2D: Cascade Elevator

Cable Ends

The ends of the cable are arguably the most important part of elevator rigging to do right. If they are handled improperly it can cause issues with rigging falling apart during impacts; this usually takes the elevator (and anything requiring it to move) completely out of commission for the match. Cascade rigging consists of at least one loop of cable per stage, which drives the motion for the next stage.

Cable Tension

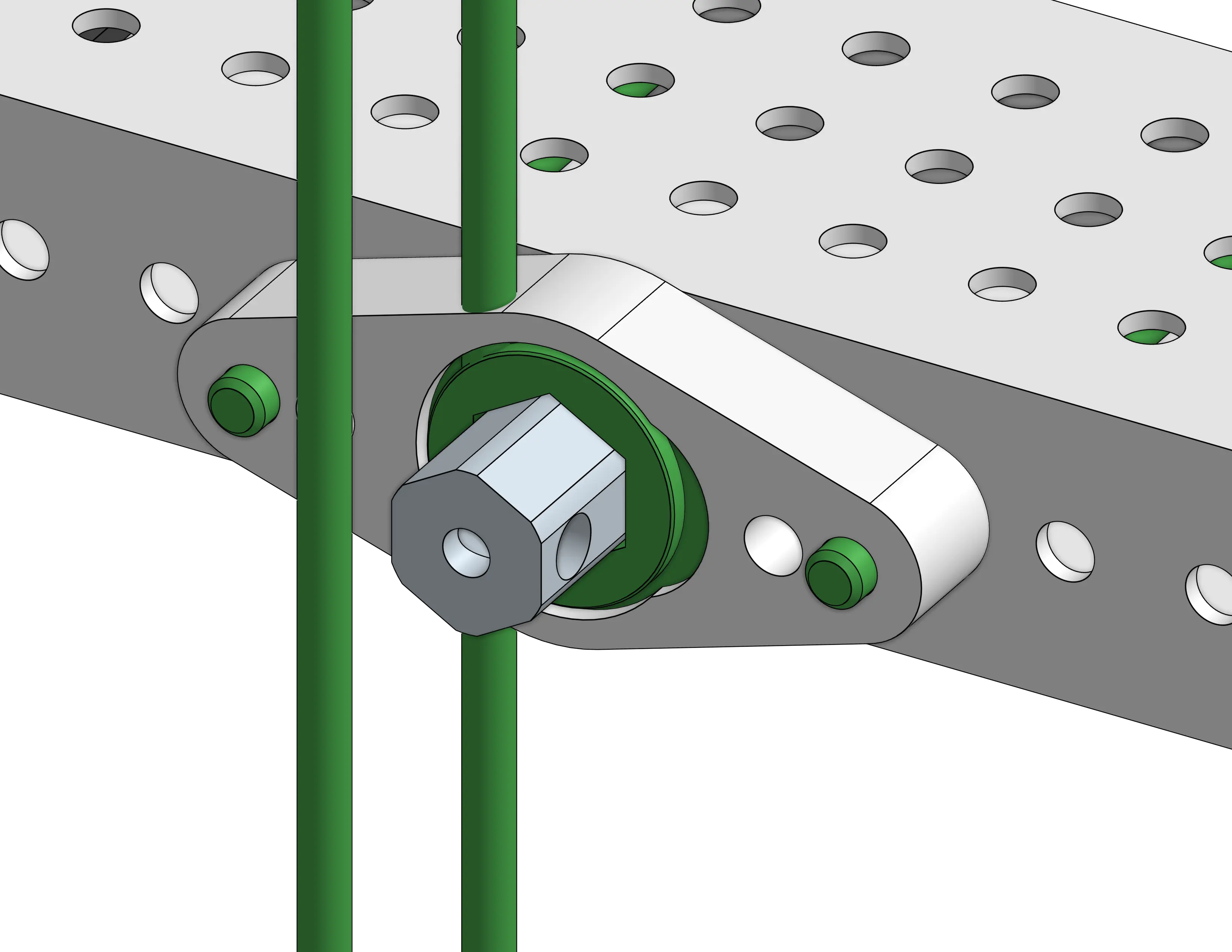

To ensure smooth motion, these cables need tensioned. One of the best ways to tension these cables is through a ratcheting cable spool. The COTS solution is to use the WCP Ratchet Plate (though an easy homemade solution can be done by cutting the end off of a ratcheting wrench and fastening it to your mechanism), with a hex shaft acting as the spool. The hex shaft gets a hole drilled in it so the cable is forced to wrap around it.

It is important to tie a self-tightening knot in the cable to prevent this from coming undone under high load. This ratcheting spool only needs to be done on one side, with a simple fixed loop on the other side. To tension properly, you will need to loosen the clamping plate before adding tension. This is for two reasons: in order to maintain sync between the stages and so that the tension gets added to each side instead of just the side with the ratchet.